[{"activity":"DE_ME_V3D","address":"K\u00f6nigbacher Str.15\r\n94496 Ortenburg, Germany","central":true,"comment":"","companyName":"Micro-Epsilon","countries":"54","deZip":"01,02,03,04,05,06,07,08,09,10,11,12,13,14,15,16,17,18,19,39,95,98,99","email":"thomas.reitberger@micro-epsilon.de","emailCc":"","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"+49 8542 \/ 168 - 90","hidePlz":false,"image":{"originalResource":{},"pid":358,"uid":1853},"internalNote":"","lName":"","map":null,"mobile":"","name":"Thomas Reitberger","phone1":"+49 8542 \/ 168 - 652","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":8721,"type":null,"uid":185,"usStates":"","website":"","worldwide":false},{"activity":"DE_MEAD-3D_Ost","address":"Lessingstr. 14\r\n01465 Langebr\u00fcck","central":false,"comment":"B\u00fcro Ost 2 3D","companyName":"Micro-Epsilon","countries":"54","deZip":"01,02,03,04,05,06,07,08,09,10,11,12,13,14,15,16,17,18,19,39,95,98,99","email":"thomas.ruemmler@micro-epsilon.de","emailCc":"andrea.huber@micro-epsilon.de","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"+49 35201 \/ 729 - 90","hidePlz":false,"image":{"originalResource":{},"pid":358,"uid":1660},"internalNote":"","lName":"","map":null,"mobile":"","name":"Thomas R\u00fcmmler","phone1":"+49 35201 \/ 729-301","phone2":"","pid":358,"products":"","regional":true,"showMail":false,"sorting":9332,"type":null,"uid":79,"usStates":"","website":"","worldwide":false},{"activity":"DE_ME_V3D","address":"K\u00f6nigbacher Str.15\r\n94496 Ortenburg, Germany","central":false,"comment":"","companyName":"Micro-Epsilon","countries":"54","deZip":"20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,86,87,88,89,97","email":"thomas.penski@micro-epsilon.de","emailCc":"","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"+49 8542 \/ 168 - 90","hidePlz":false,"image":{"originalResource":{},"pid":358,"uid":1855},"internalNote":"","lName":"","map":null,"mobile":"","name":"Thomas Penski","phone1":"+49 8542 \/ 168 - 492","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":9235,"type":null,"uid":184,"usStates":"","website":"","worldwide":false},{"activity":"DE_MEAD-3D_Nord-West","address":"K\u00f6nigbacher Str. 15\r\n94496 Ortenburg","central":false,"comment":"B\u00fcro Nord-West 3D","companyName":"Micro-Epsilon","countries":"54","deZip":"20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,37,38,40,41,42,43,44,45,46,47,48,49,58,59","email":"jan-thorben.willenbrink@micro-epsilon.de","emailCc":"3D@micro-epsilon.de","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"+49 8542 \/ 168 - 92 718","hidePlz":false,"image":{"originalResource":{},"pid":358,"uid":1662},"internalNote":"","lName":"","map":null,"mobile":"","name":"Jan-Thorben Willenbrink","phone1":"+49 8542 \/ 168 - 718","phone2":"","pid":358,"products":"","regional":true,"showMail":false,"sorting":9333,"type":null,"uid":78,"usStates":"","website":"","worldwide":false},{"activity":"DE_MEAD-3D_Sued-West","address":"Manfred-W\u00f6rner-Str. 101\r\n73037 G\u00f6ppingen\r\nGermany","central":false,"comment":"B\u00fcro S\u00fcd-West 3D","companyName":"Micro-Epsilon","countries":"54","deZip":"35,36,50,51,52,53,54,55,56,57,60,61,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,86,87,88,89,97","email":"jens.hoeppner@micro-epsilon.de","emailCc":"3D@micro-epsilon.de","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"+49 8542 \/ 168 - 92 670","hidePlz":false,"image":{"originalResource":{},"pid":358,"uid":1659},"internalNote":"","lName":"","map":null,"mobile":"","name":"Jens H\u00f6ppner","phone1":"+49 8542 \/ 168 - 670","phone2":"","pid":358,"products":"","regional":true,"showMail":false,"sorting":9331,"type":null,"uid":80,"usStates":"","website":"","worldwide":false},{"activity":"DE_ME_V3D","address":"K\u00f6nigbacher Str.15\r\n94496 Ortenburg, Germany","central":true,"comment":"","companyName":"Micro-Epsilon","countries":"13,54","deZip":"80,81,82,83,84,85,90,91,92,93,94,96","email":"viktor.kirchgessner@micro-epsilon.de","emailCc":"","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"+49 8542 \/ 168 - 90","hidePlz":false,"image":{"originalResource":{},"pid":358,"uid":1850},"internalNote":"\u003Cp\u003E\u003Cstrong\u003EAT,DE\u003C\/strong\u003E,EE,IS,LT,LV\u003C\/p\u003E","lName":"","map":null,"mobile":"","name":"Viktor Kirchgessner","phone1":"+49 8542 \/ 168 - 478","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":8713,"type":null,"uid":188,"usStates":"","website":"","worldwide":false},{"activity":"DE_ME_V3D","address":"K\u00f6nigbacher Str.15\r\n94496 Ortenburg, Germany","central":false,"comment":"","companyName":"Micro-Epsilon","countries":"54","deZip":"80,81,82,83,84,85,90,91,92,93,94,96","email":"tobias.wimmer@micro-epsilon.de","emailCc":"","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"+49 8542 \/ 168 - 90","hidePlz":false,"image":{"originalResource":{},"pid":358,"uid":53102},"internalNote":"\u003Cp\u003EAT,DE,EE,IS,LT,LV\u003C\/p\u003E","lName":"","map":null,"mobile":"","name":"Tobias Wimmer","phone1":"+49 8542 \/ 168 - 454","phone2":"","pid":358,"products":"","regional":true,"showMail":false,"sorting":8978,"type":null,"uid":212,"usStates":"","website":"","worldwide":false}]

Kontakt

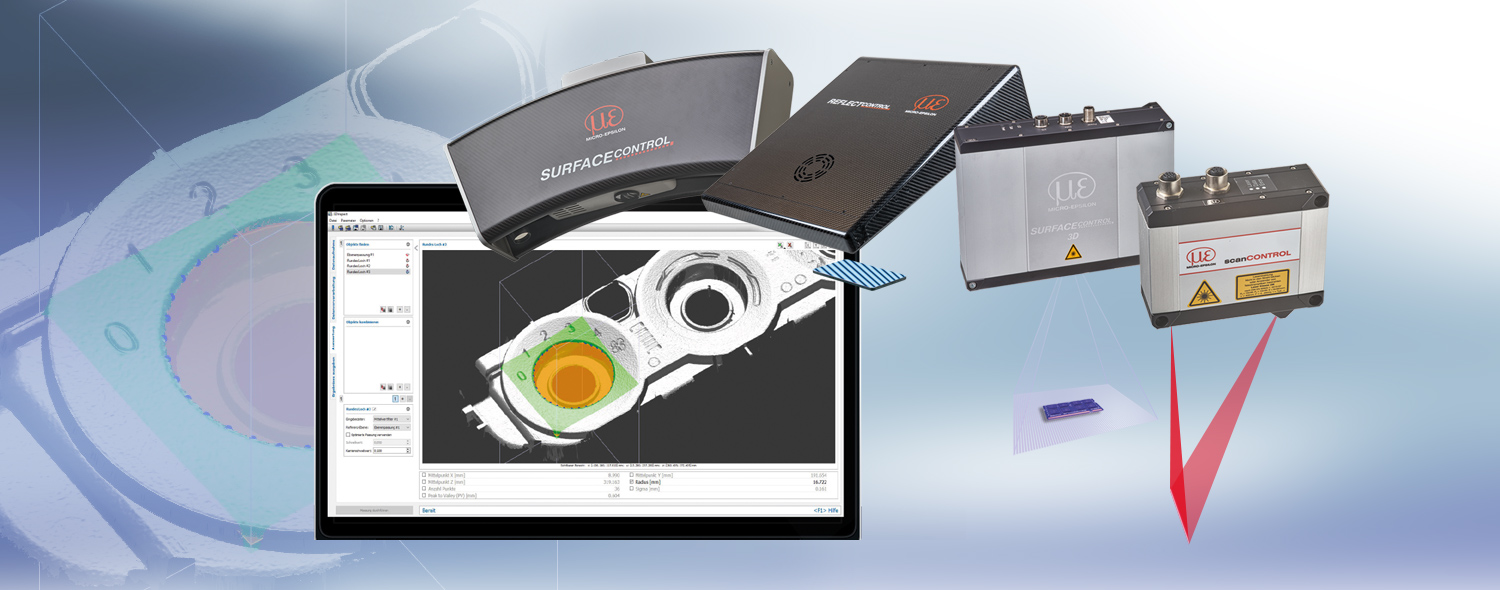

Micro-Epsilon Messtechnik 3D-Zentrale

Ihr zentraler Ansprechpartner:

Thomas Reitberger

Ihr regionaler Ansprechpartner:

Thomas Rümmler

Ihr regionaler Ansprechpartner:

Jan-Thorben Willenbrink

Ihr regionaler Ansprechpartner:

Jens Höppner

Ihr zentraler Ansprechpartner:

Viktor Kirchgessner

Ihr regionaler Ansprechpartner:

Tobias Wimmer